Search This Supplers Products:HVAC ChillersIntegrated Air Conditioning UnitHeat PumpComposite MaterialAir TreatmentFan Coil Unit

- Home

- About us

- Products

- Faqs

- Product Customization & Applications

- Technical Documents & Support

- System Operation & Troubleshooting

- Product Performance & Advantages

- Procurement & Order

- Maintenance & Care

- Installation & After-sales

- Air Filter FAQ

- Air-Cooled Chiller Unit – FAQ

- Modular Air-Cooled Cold (Hot) Water Unit – FAQ

- Natural Cooling Air-Cooled Screw Chiller – FAQ

- Variable speed Scroll Air-CooledModular Units—FAQ

- News

- Certificate

- Contact us

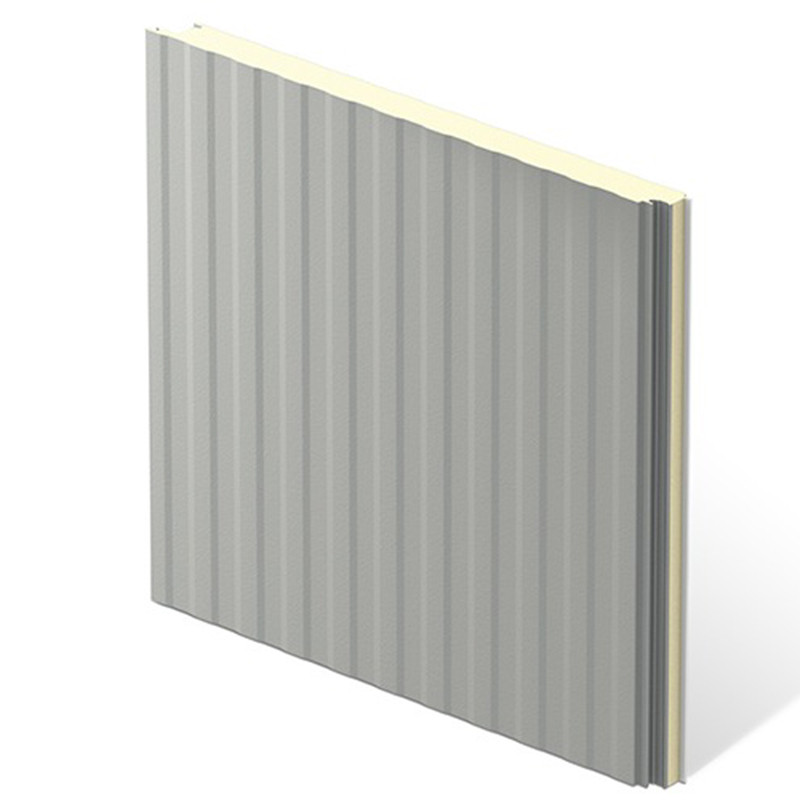

Insulated Color Steel Sandwich Panel | PU/EPS/Rock Wool Composite Wall & Roof Panel

- group name

- Color Steel Sandwich Panel

- Min Order

- 1 piece

- brand name

- Aurashu HVAC System Air Solutions Manufacturer

- update time

- Sat, 06 Dec 2025 05:37:59 GMT

Paramtents

Fire Resistance Up to Class A (Rock Wool), Class B1 (PU)

Sandwich Material A-grade flame-retardant core

Frame Material aluminum alloy or plastic steel frame

Surface Coating Material corrosion-resistant coated

Bearing capacity 150kg-200kg

Steel Sheet Thickness 0.4mm–0.8mm (inner & outer skin)

Packging & Delivery

-

Min Order1 piece

Briefing

Durable insulated Color Steel Sandwich Panels for wall, roof, cleanroom and cold storage. Fire-resistant and highly thermal-insulated.

Detailed

Product Overview – Color Steel Sandwich Panel

Our Color Steel Sandwich Panels are prefabricated building materials made of two color-coated steel sheets with a core insulation layer such as PU (Polyurethane), EPS (Expanded Polystyrene), Rock Wool, or Phenolic Foam. These panels offer excellent thermal insulation, fire resistance, acoustic performance, and fast installation.

They are widely used in industrial buildings, cleanrooms, cold storage, prefab houses, and modular construction systems, offering long-term durability and cost efficiency. Available in a variety of thicknesses, coatings, and core materials.

Why Choose Our Color Steel Sandwich Panel

Excellent thermal insulation performance: Excellent thermal insulation thanks to core materials like PU, rock wool, or glass wool, reducing energy costs.

High strength and stable structure: High-strength color-coated steel offers structural integrity and load-bearing performance.

High fire retardancy: Fire-resistant cores (e.g., rock wool, MgO) meet Class A standards for fire safety.

Corrosion-resistant, moisture-resistant, and weather-resistant: Anti-corrosion coatings ensure durability in humid, coastal, or chemical-prone areas.

Beautiful appearance, available in multiple colors:Smooth, attractive surfaces with customizable colors and textures to suit various aesthetics.

Quick and easy installation:Modular interlocking design allows fast and easy installation, shortening project timelines.

Frequently Asked Questions (FAQ)

Q1: :Is it corrosion-resistant?

A: Yes, with galvanized/aluzinc and color coating layers, the panel offers excellent corrosion resistance for outdoor and humid environments.

Q2: Can the color and size be customized?

A: Yes, panel color (RAL series), length, thickness, and edge joint types (tongue-and-groove, concealed fastener, etc.) can be customized.

Q3: Are these panels fire-resistant?

A: It depends on the core material. Rock wool is Class A non-combustible, PU is B1/B2 fire-rated, while EPS is flammable.